03.07.2024

Longship; Carbon Catcher Simulator (OTS) in Brevik

Brevik CCS in Norway is part of the Longship project, which aims to significantly reduce CO2 emissions from cement production. A crucial component at Brevik CCS is a custom-designed simulator.

The Operator Training Simulator (OTS) will play a vital role in the CCS project in Brevik, by allowing operators to learn and practice the operation of a chemical process – in a virtual and risk-free environment. OTS can help operators master operations under various conditions and handle any unforeseen events that may arise during the process.

Initiative from Brevik CCS

Project Manager Tor Gautestad at Brevik CCS has been the driving force behind the OTS sub-project. – I initiated the process by asking Aker Carbon Capture about the possibility of creating a digital twin to simulate the process and train operators. They confirmed this, based on offshore projects with Kongsberg Digital. Although the Brevik facility is smaller than the offshore platforms Aker and Kongsberg Digital have worked with previously, the OTS solution in Brevik is also very complex, says Tor Gautestad.

Aker Carbon Capture has provided the capture technology used at Brevik CCS. MAN Energy Solutions has contributed with Carbon Capture Heat Recovery technology, which recovers heat from the compression system for use in the carbon capture plant, making the entire process more energy-efficient.

Innovation and Knowledge Sharing

Longship is Europe’s first approved full-scale CCS project. Its purpose is to demonstrate that CO2 management is safe and feasible. Longship aims to be a significant contributor to the development of CCS as a climate measure. This includes developing solutions and sharing knowledge with subsequent projects. – OTS is a prime example of a contribution from Longship, where players like Kongsberg and Aker develop customized CCS solutions – based on offshore experience. OTS solutions stemming from Norwegian knowledge environments can provide important learning for upcoming CCS plants, says Senior Advisor Hans Jørgen Vinje at Gassnova.

Training Content

OTS ensures that operators have the necessary knowledge and skills, including in-depth knowledge of CCS technology. This enables them to handle equipment and processes efficiently and safely. The training covers all aspects of CO2 capture, compression, transport, and storage. The program includes technical training which provides a comprehensive overview of capture technology, compression techniques, and equipment used in the process. Safety and emergency procedures are other critical components. Environmental and regulatory requirements cover knowledge of environmental regulations and measures, to minimize risk of harm.

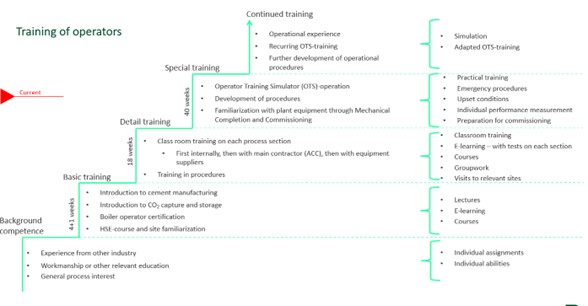

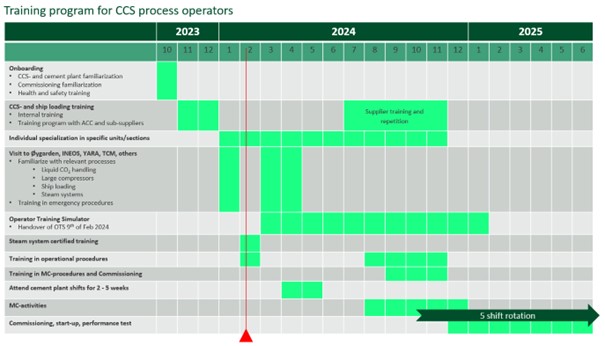

Comprehensive Training Plan

OTS involves a carefully planned, phased training, evaluation, and certification process.

Training for operators and maintenance workers is followed up with further education and refresher courses. Operators’ skills are regularly evaluated through tests and practical assessments. Follow-up programs ensure that competence is maintained. Digital tools and simulation technology are used to provide realistic training and monitor training progress.

– OTS increases efficiency and reliability, as well-trained operators contribute to efficient operations, reduce downtime, and increase productivity. Continuous training also promotes a culture of innovation, where operators can suggest improvements based on practical experience. We can simulate different scenarios and see the effects of changes before implementing them in reality. This provides us with valuable data and insights, Tor continues.

Corporate Support

Heidelberg Materials is a global building materials company who owns and operates the Brevik CCS project. The CCS facility in Brevik is the world’s first at a cement plant. Based on the knowledge gained here, Heidelberg Materials has launched several other carbon management projects, some with capture rates which will decarbonize the respective cement plants by 2030.

– Our owners see the potential in the simulator, which can play a crucial role in carbon management at the group’s other cement plants. The management at Heidelberg Materials sees the potential in OTS technology, both for training operators and engineers, and for optimizing operational processes, concludes Tor Gautestad at Brevik CCS.

Collaboration with TCM

There is also cooperation with the Technology Centre Mongstad (TCM), which has more than 12 years of experience operating a CO2 capture facility. About 20 operators from Brevik CCS were at TCM earlier this year to learn more about their experiences. It has proven important to be connected to a real capture facility on a smaller scale, where CO2 capture has been tested in various operational environments over time. This exchange of experiences will continue when Brevik CCS becomes operational.