Longship project timeline published

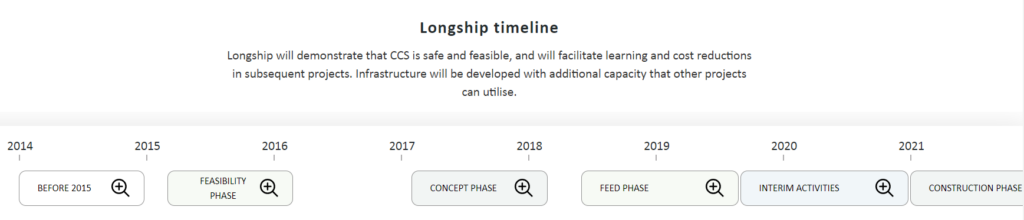

Do you want to know more about what Norway’s Longship CCS project has achieved so far? Gassnova has just published a timeline where you can explore studies and reports released ranging from its inception up to today.

Longship is one of the first CCS projects in the world aimed at developing an infrastructure with the capacity to store significant amounts of CO2 from multiple countries. Through Longship, Norway is right at the cutting edge of the development of a technology that could be crucial for achieving climate goals.

History of the Longship project

In autumn 2018, it was decided that full-scale work could commence, and both the Hafslund Oslo Celsio and Heidelberg Materials capture projects were able to carry out front end engineering design (FEED) planning. Equinor, Shell and TotalEnergies also carried out FEED planning for the transport and storage project through the Northern Lights partnership.

Working on the realisation of gains and knowledge sharing has been key to the work of Gassnova and industry actors. An important part of the work has been to show that the Norwegian full-scale project could pave the way for more CCS projects in Europe.

Hafslund Oslo Celsio and Heidelberg Materials delivered their FEED reports in late autumn 2019. The transport and storage FEED planning was completed in Q1 2020, and in May of the same year, the Northern Lights partnership submitted its plan for the development of the transport and storage part of the full-scale project. Gassnova’s reports from the pilot project phase, including an evaluation of the capture projects, was also submitted to the Norwegian Ministry of Petroleum and Energy before summer 2020. The reports form an important part of the authorities’ decision-making basis.

On 21 September 2020, the Norwegian government launched the “Longship” CCS project. In January 2021, the project was approved by the Storting.

What you can read on the Longship timeline

On the Longship timeline, you can see how the project has developed from its inception up to today. It is continuously updated with important events for the project.

You will also find feasibility studies, concept studies and analyses that support the basis for Longship investment decisions. In addition, there are also links to the lessons learned and regulatory learning reports.

Concept study from 2015 has been published

The project started with the concept study which was completed in 2015. Until now, only the summary has been published, but Gassnova is now publishing the entire study.

The CCS project, which eventually resulted in Langskip, was developed through many phases and took place over many years. The kick-off for what later became Langskip began with the concept study from 2015. Later, a feasibility study (2016), concept studies (2017) and preliminary project studies (2019) were carried out before the Storting decided to implement the project in 2020. All studies are published on CCSNorway.

Gassnova’s conceptual study identifies several emission sources and storage locations that could be technically suitable for CO2 handling and industrial players that could be interested in participating in further feasibility studies. The industrial players also gave input to the state on what framework conditions they thought were necessary. There has been a significant development in Norwegian and international climate policy in recent years, 2015 and the input given in the study must be seen in the light of the fact that it was given in 2015.

The value of trust between private companies and authorities

The stakeholders involved in the CCS project Longship all highlight trust as a prerequisite for the success of the project. Longship are being realized even though important regulatory issues have not yet been clarified, and it is unclear how the authorities will enforce the regulations.

Unique approach has brought gradual trust

The Longship project has been developed through a step-by-step project development process, with several decision points for both industry and government. Gassnova believes this approach has been instrumental in gradually building trust between the public and private sectors before final investment decisions were made. During the project development process, both the industrial projects and the state aid agreements have matured.

Unusually great openness and flexibility

In light of the government’s and industry’s joint goal of realizing a CCS chain, all parties have shown an openness and flexibility that is not common for other projects.

– The goal we wanted to achieve well over a decade ago is now becoming a reality. It is a strong result of a fruitful collaboration between all stakeholders across the CCS value chain in Norway, said Giv K. Brantenberg, Managing Director HeidelbergCement Northern Europe during the Northern Lights Summit 2022.

Hafslund Oslo Celsio, Northern Lights and the Ministry of Petroleum and Energy have also pointed out that trust between private companies and authorities has been important for the success of Longship.

This article was written based on the report «Regulatory lessons learned from Longship», which is based on the experiences gained from the Longship project.

Amine-based carbon capture produces small emissions of amines

The capture operators Heidelberg Materials (formerly Heidelberg Materials) and Hafslund Oslo Celsio in the Longship project have tested their capture technologies on their own flue gas. Both note that this has been important to ensure that the amine emissions will not exceed certain levels and the degradation products will be below the limit set by the authorities.

Method for emission limits for CO2 capture facilities

An amine-based CO2 capture facility will produce small amounts of amine emissions to air. Amines can react with other substances in the atmosphere to form nitrosamines and nitramines. Some nitrosamines and nitramines have shown carcinogenic effects in animal experiments. Any spread in the environment is therefore not acceptable and should be limited. The Institute of Public Health has given recommendations for how much nitrosamine and nitramine can be allowed in air and drinking water. This has given the Norwegian environmental authorities a method for setting emission limits for CO2 capture facilities.

An advanced model is used to calculate what a given amount of amine in the discharge results in emissions in the form of nitre and nitrosamines. This model uses advanced atmospheric chemistry, dispersion patterns and historical meteorological data to, among other things, calculate the amount of nitre and nitrosamines in the nearest drinking water source. Safety factors have been added and then the emission limit of amine has been set. The emission limit is related to how much flue gas is produced. For each of the capture facilities at Klemetsrud and in Brevik, an emission permit has been granted for 1 mg amine/Nm3 flue gas.

Pilot tests have documented suitable technology

The selected CO₂ capture technologies at the two capture facilities have provided documentation of specific performance related to CO₂ capture, breakdown of amines and possible emissions of amines to air from previous test sites. Documentation on these parameters for specific flue gases from a cement plant and a waste incineration plant is available.

Both capture sites ran a pilot test campaign on the chosen technology on site. The pilot tests documented that the technology was suitable for the purpose and would meet the strict emission requirements when exposed to the specific flue gas.

Both Heidelberg Materials and Hafslund Oslo Celsio noted that this has been important to ensure that the amine emissions will not exceed certain levels and that the degradation products will be below the limit set by the authorities.

See related articles on the Norwegian Environment Agency’s website, which also contains the decisions made for Heidelberg Materials Brevik and Hafslund Oslo Celsio (“Decision on permit for polluting activities” – in Norwegian):

• CO2-fangst reduserer Oslos utslipp

• Karbonfangst vil halvere utslippene fra Heidelberg Materials Brevik

This article was written based on the report «Regulatory lessons learned from Longship», which is based on the experiences gained from the Longship project.

Sharing learning about regulation of CCS chain

Longship will provide learning related to the regulation and incentivization of CO2 management activities that others can benefit from. As Langskip is the first entire CCS chain to be regulated in Norway, the interface between regulatory authorities had to be clarified.

How dangerous are CO2 emissions?

One of the main risk areas for the CCS chain is the risk associated with handling large amounts of CO2.

CO2 differs from hydrocarbons in many ways, and it is important to note that it does not ignite like hydrocarbons. There is therefore no risk of explosion due to ignition. CO2 is not harmful to living organisms in low concentrations. HSE risks are linked to overpressure and leakage of large volumes. Leakage of large volumes with high concentrations of CO2 is harmful to most living organisms and should be avoided. Read more about safe storage of CO2 here.

The interface between regulatory authorities needed clarification

Experience from the Langskip project showed that the interface between the regulatory authorities, The Norwegian Directorate for Civil Protection (DSB) and the Petroleum Safety Authority Norway, needed clarification.

DSB (supervisory authority on land) regulates plant handling of hazardous substances, including pressurized CO2. The Directorate has given the necessary consents to the industrial partners in Langskip.

The Petroleum Safety Authority Norway (offshore supervisory authority) has the regulatory responsibility for safety, working environment, preparedness and safety in the petroleum sector. They have developed new regulations on safety and the working environment when transporting and injecting CO2 on the continental shelf (the CO2 safety regulations).

During the planning of the transport and storage infrastructure in Longship, it turned out that it was not clear where DSB’s responsibility stopped and the Petroleum Safety Authority Norway began. Regarding the intermediate storage of CO2 on land before transport in a pipeline for permanent storage in a reservoir under the seabed, DSB and the Petroleum Safety Authority Norway have generally agreed on the following:

- DSB is the responsible authority for handling CO2 on land. This applies both at the capture facilities and in the intermediate storage before transport by pipeline.

- The Petroleum Safety Authority Norway is responsible for transport in the pipeline from the export pump upstream. It includes the necessary equipment and piping systems for operation and maintenance of the pipeline, as well as equipment and systems for well monitoring and control, and associated emergency and safety systems in connection with the pipeline and injection well. However, this is an interface that can be complicated for the receiving facilities. There may therefore be a need for concrete assessments of where the interface should go.

This article was written based on the report «Regulatory lessons learned from Longship», which is based on the experiences gained from the Longship project.

Tailored state aid agreements are necessary

Experience from the Longship project shows that, due to a lack of commercial incentives for industry partners and whole chain risks that could not be absorbed by industry partners, tailored state aid agreements were necessary.

State aid for industry partners

Since CCS was not commercially viable when the Longship project began, it was necessary to provide state aid to industry partners.

The high proportion of state aid has made it necessary for the state to follow up on the projects.

Cost sharing required up to a maximum level

Since the Longship projects are the first of their kind, the level of uncertainty in each project is higher than you would normally encounter in large industrial projects. Industry partners therefore required cost sharing up to an agreed maximum level (related to both investment and operations).

Entering dialogue with potential customers

Northern Lights has identified a business case for carbon transport and storage: The state aid agreement provides Northern Lights with incentives to enter into dialogue with potential customers across all of Northern Europe. Northern Lights’ potential future profits will be based on the tariff paid by potential new customers.

Elements of regulations that have been challenging

Elements of regulations have been challenging for industry partners. For example, there are no incentives for carbon capture and storage from biogenic sources and the liability for damages related to any CO2 leakages in the chain is not always logically allocated. This is set through the state aid agreements.

Must comply with the Norwegian Public Procurement Act

The extensive proportion of state aid means that industry partners must comply with comprehensive procurement procedures from the Public Procurement Act. For some industry partners, this created a need to acquire new competencies.

This article was written based on the report «Regulatory lessons learned from Longship», which is based on the experiences gained from the Longship project.

The film about Longship

The biggest climate project ever undertaken by Norwegian industry has a name: Longship. It is one of the first projects in the world to develop the infrastructure to permanently store significant amounts of carbon two to three kilometres beneath the North Sea seabed.

The film about Longship was produced by the Maverix production company, and was shot in summer 2021 at the Viking Ship Museum in Bygdøy. The film was released in Norwegian, English, German and French. It was also shown at Expo 2020 Dubai in the Norway Pavilion.

CO₂ footprint tool for CCS

The calculated CO2 footprint has not previously been found for the Norwegian CCS value chain. Gassnova therefore established a tool that could perform calculations of the CO2 footprint in line with current ISO standards.

Do not emit more CO₂ than is stored

The purpose of CCS is to reduce CO2 emissions by capturing and permanently storing CO2 in underground or subsea reservoirs. Since CCS requires extensive investments, it is important that far more CO₂ is stored than what is emitted as a result of the construction, operation and decommissioning of the CCS chain.

About Gassnova’s carbon footprint calculator

The tool is based on an Excel spreadsheet model and the greenhouse gas emission factors are taken from open and recognized databases. Gassnova has used this tool to calculate the carbon footprint of the Longship project. The following alternative value chains are calculated:

Annual catch of 400,000 tonnes of CO₂ at Heidelberg Materials in Brevik, transport by boat 585 km to Northern Lights’ reception facility in Øygarden in Western Norway, pipe transport 100 km offshore to a warehouse 2500 meters below the seabed.

Annual catch of 400,000 tonnes of CO₂ at Klemetsrud in Oslo, transport by boat 700 km to Northern Lights’ reception facility in Øygarden, pipe transport 100 km offshore to a warehouse 2500 meters below the seabed.

Annual catch of 800,000 tonnes of CO₂ in Brevik and Klemetsrud in total, transport by boat the same distances as above, pipe transport 100 km offshore to a warehouse 2500 meters below the seabed.

The project partners Fortum Oslo Varme, Heidelberg Materials and Northern Lights have contributed consumption figures for their parts of the value chain.

Contact us if you need similar calculations of CO₂ footprint

In collaboration with DNVGL and Carbon Limits AS, Gassnova has developed a tool for calculating the amount of CO₂ emitted when facilities for capture, transport and storage of CO₂ are to be built, operated and decommissioned. The tool is not commercially available, but a version without consumption figures and emission factors can be obtained by contacting Gassnova.

Read more about carbon footprints here.

Here you can also read about the CO₂ footprint from Longship, and CO₂ footprint calculations from 2020.

CCS projects needs specific and concrete goals

Experience from the Longship project shows that the use of specific and concrete goals early in the project phase should be given high priority.

The project goals of Longship

To achieve the societal goal, the Norwegian government has defined four effect goals.

The longship project (which is the largest climate project in Norwegian industry ever) will:

- provide knowledge that shows that it is possible and safe to carry out full-scale CO₂ management

- provide productivity gains for future projects through learning and scale effects

- provide learning related to the regulation and incentivization of CO₂ management activities

- facilitate business development

This is what the experience shows

The project goals describe the desired effect rather than specific goals. This has led to different interpretations of the project goals among the partners. On the one hand, this has enabled the partners to develop their projects to better suit their business base. On the other hand, it has led to challenging discussions between Gassnova and industrial partners regarding the desired performance that is used as a basis in the design of technical solutions.

Defining clear project goals, for example by using the SMART principle and ensuring alignment between all project stakeholders, should be a high priority at an early stage. This is especially relevant for projects with a complex stakeholder picture, which is usually the case with CCS projects.